Aug 05 2025

VIEW MORE

Made of cross-linked polyolefin.

Mostly used to provide sealing and protection for bifurcated cable, especially for the branch cable lapping on the main cable.

Shrink temperature: Start at 90℃, and fully recovered at 130℃.

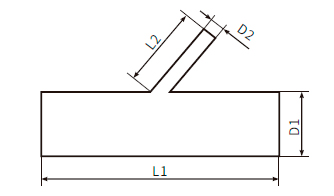

| Product No. | L1/±5mm | L2/±3mm | D1/mm | D2/mm | ||

| As Supplied | After Recovered | As Supplied | After Recovered | |||

| WRSY-28/13 | 120 | 38 | ≥28 | ≤13 | ≥9 | ≤4 |

| Property | Test Method | Standard Value | ||

| Physical properties | Tensile Strength | ASTM-D-2671 | ≥12MPa | |

| Elongation at Break | ASTM-D-2671 | ≥350% | ||

| Tensile Strength after Aging | ISO 868 | ≥10MPa | ||

| Elongation at Break after Aging (130℃, 168h) | ASTM-D-2671 | ≥280% | ||

| Heat shock(200℃, 4h) | UL 224 | No dripping, flowing or cracking | ||

| Low temperature flexibility | ISO 974 | -40℃ | ||

| Oxygen index | ISO 4589 | ≥28 | ||

| Dielectric strength | IEC 60243 | ≥20kV/mm | ||

| Solvent resistance (23℃,24h) | Gasoline | Tensile strength | ASTM-D-2671 | ≥10MPa |

| Elongation at break | ASTM-D-2671 | ≥280% | ||

| Diesel oil | Tensile strength | ASTM-D-2671 | ≥10MPa | |

| Elongation at break | ASTM-D-2671 | ≥280% | ||

| Acid & alkali | Tensile strength | ASTM-D-2671 | ≥10MPa | |

| Elongation at break | ASTM-D-2671 | ≥280% | ||

| Property | Test Method | Standard Value |

| Tensile Strength | ASTM-D-638 | ≥10MPa |

| Elongation at Break | ASTM-D-638 | ≥300% |

| Dielectric Strength | IEC 60243 | ≥20kV/mm |

| Volume Resistivity | IEC 60093 | ≥1×1013 Ω·cm |